HIGH QUALITY - FAST SERVICE

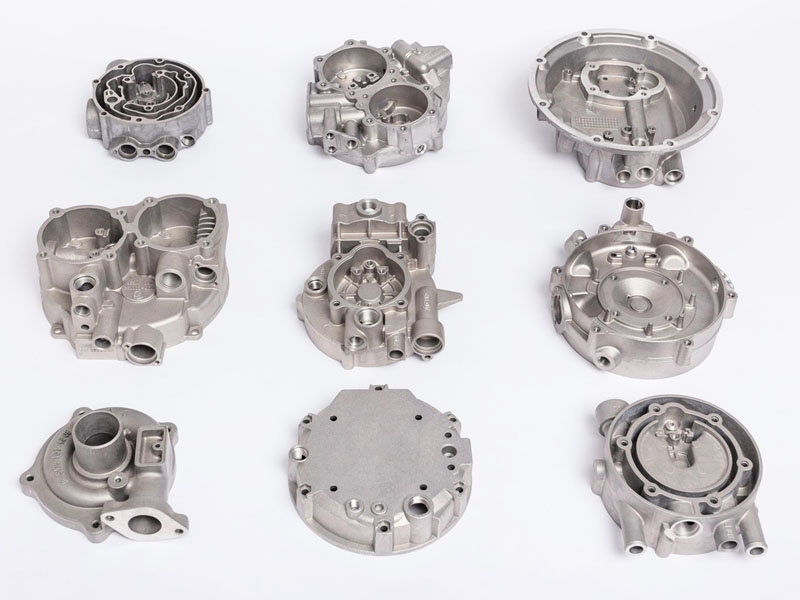

Manufacturing of small mechanical components and precision machining for mechanical engineering and automotive industries according customers technical specification.

Quality

IMP makes production quality its successful strategy. Our main target is to fully meet our customer’s need.

Product sector

IMP is well know in the Italian and European market as a leading company in manufacturing small mechanical components and carrying out precision machining for multiple sectors: Automotive, Motorcycle, Pneumatics and Gas.

From Project to Product

IMP can supply complete items, starting from customers project until the delivery of the finished product.

IMP is a leader in mechanical maching from casting die and bar. IMP is able to produce precision parts based on customers drawings and high quality finished products.

IMP is a fast, innovative and flexible structure set up and organized to give quick answer to your requests. Our staff is continuously involved in every company decision, providing the necessary skills and experience to achieve each goal. The management of production is computerized improving time management and order analysis for satisfy your demand as quickly as possible.

Strenght of IMP is concentrated on their customers satisfaction, who particulary appreciate the tailored response to their demands.

Our company stands out for finished products of excellent quality and a wide range of additional services such as impregnation, deburring, sandblasting ,tumbling, galvanic treatments and complete assembly.

IMP is a certain choice for quality and reliability. Our quality system is certified UNI EN ISO 9001:2015.

Machineries, tools and equipments ensure the reliability and detectability of the processes.

All operational staff is daily involved and oriented on meeting all needs of customer.

Machine Tools

Our machineries inside the company are:

- 10 Transfer CNC and mechanical with rotating table multi-station

- 6 Machining centers at 4 axes Robodrill Fanuc

- 3 CNC lathes

- 4 Swiss-type lathes with 16 controllated axes with bar passages ø2 to 32

- 5 Lathes with bar feeder 12 controllated axes and bar passages until ø65

- 1 Surface grinding machine

- 1 Impregnation machine for aluminium die casts

- 1 Sandblasting with glass micro-beads

- 6 Washing plants by water and by solvent

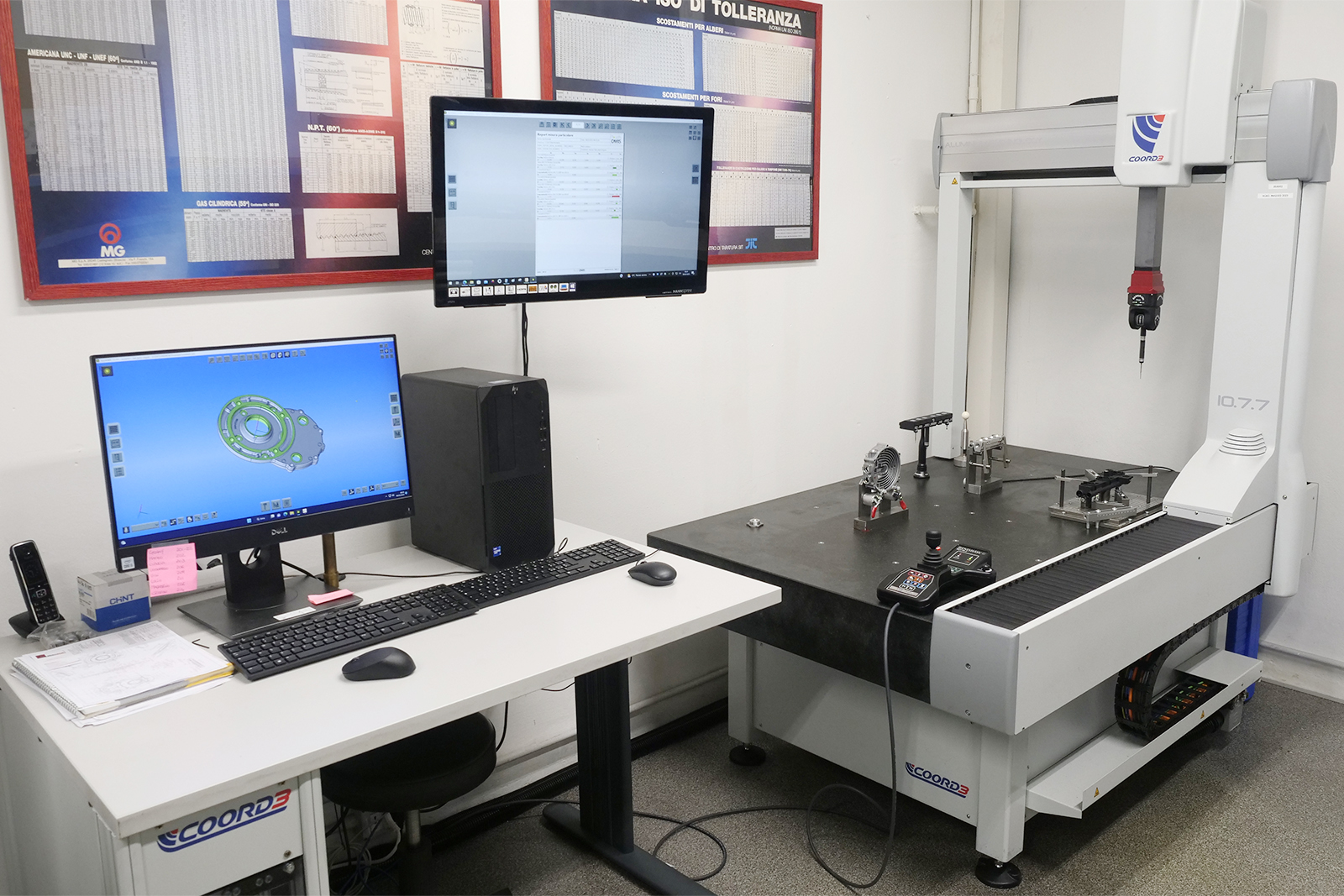

Metrology room

- 1 Machine measure CMM “COORD 3 “ MOD. ARES NT

- 2 CMM manuals

- 2 Altimeters

- 1 Profilometer QPT cv 120

- 2 Profile Projectors

- 1 Rugosimetro

- 1 Digital Microscope Optech

- 2 Stereo Microscopes Askania